EZE Shoring is a versatile lightweight, high performance composite shoring system, ideal for reducing manual handling injuries. For use in the construction sector when either hand digging or using a mini excavator, to form a trench in soils that are self supporting.

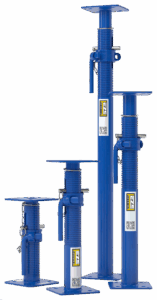

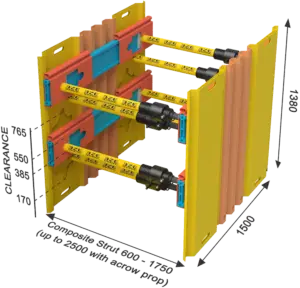

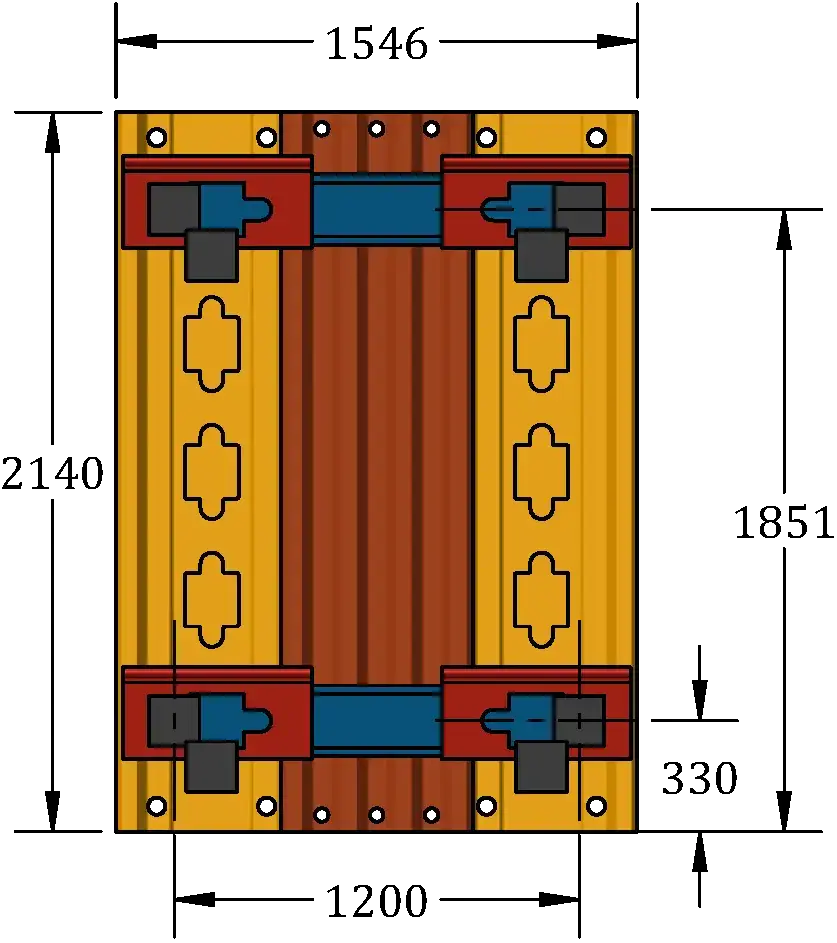

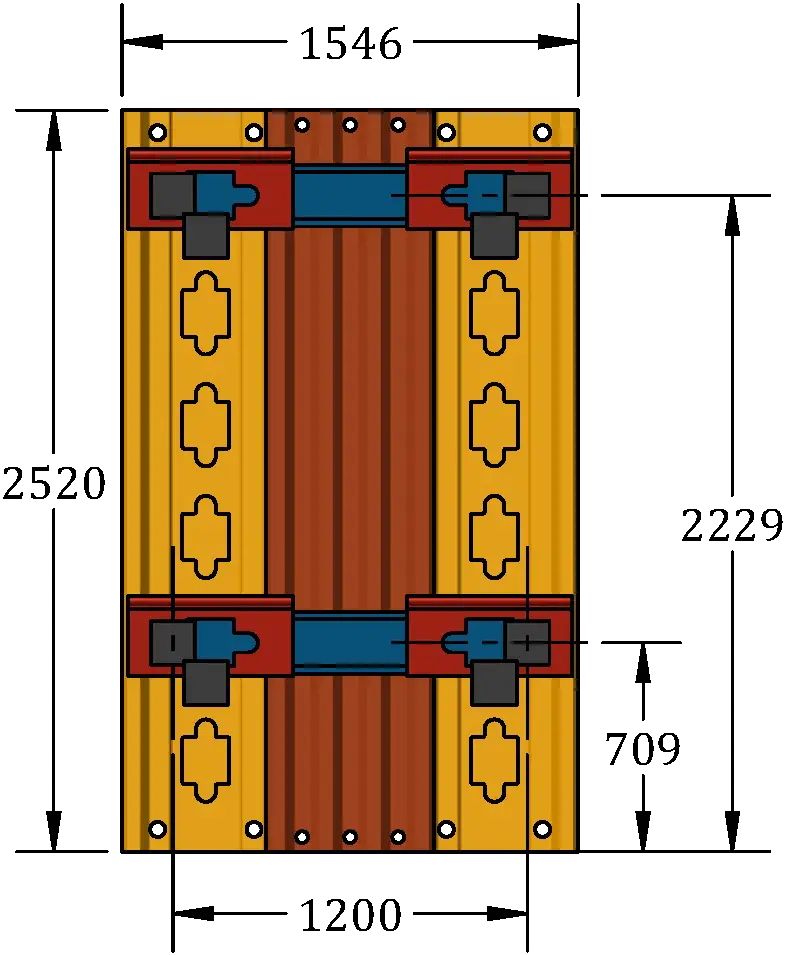

The high performance composite HUBshore system provides shoring solutions for excavation depths from shallow depths – 620mm up to 2500mm – incorporating EZE Strut to support trench widths ranging from 600 mm to 1750 mm. (Up to 2500 mm with a metallic prop).

Always inspect the products for accidental damage prior to use. Always ensure all struts are correctly inserted prior to use. Do not allow personnel within the trench whilst the excavator is digging. Ensure all personnel are well clear of its operation.

Where ever possible only access and work in the trench between supported HUBshore piles. Never enter via ends/faces of an unsupported excavation.

Always work from a position of safety. Avoid, working above on an unsupported edge, an unprotected edge or under a suspended load.

Always ensure operatives are safely out of the excavation before removal of units. (Reversal of the installation)

Do not overload the EZE Struts beyond their stated safe working range. Ensure when in their final positions, the piles sits square and vertical with continuous contact against the trench wall.

When inside the trench, operatives should continually monitor the walls for change of conditions such as excessive movement or cracks and water seepage.

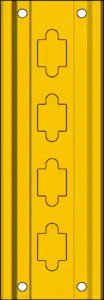

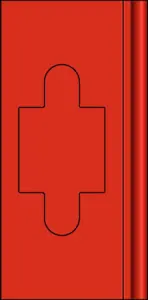

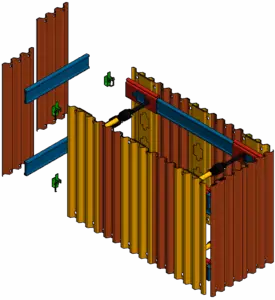

Adjust the EZE Struts to the approximate required width of the trench. Stand up two EZE HUB piles. Insert both ends of the strut into the EZE HUB pile recess with the corner of the strut base plate upright.

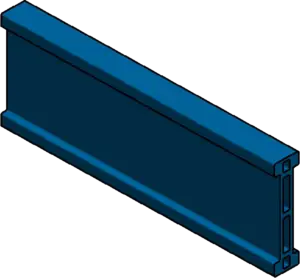

Position two EZE Sliders onto the end of each EZE Waler.

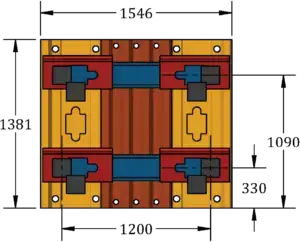

Figure 10

Lift the EZE Hub pile sub assembly and position at the top of the battered end of the excavation – 2 persons required. With one person either side of the excavation, lower the sub assembly into position.